Spider UL

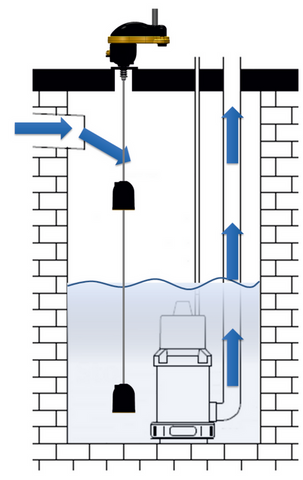

The rods attached to the body allow the level regulator to work in narrow spaces and in difficult environments with turbulent waters.

PATENTED PRODUCT

Applications:

Download:

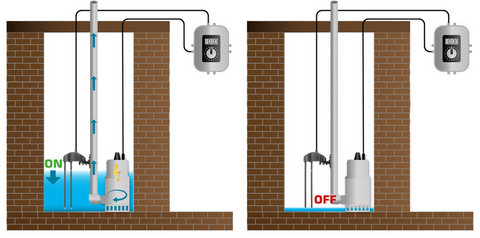

Principle of Operation

Based on the electrical conductivity of the water

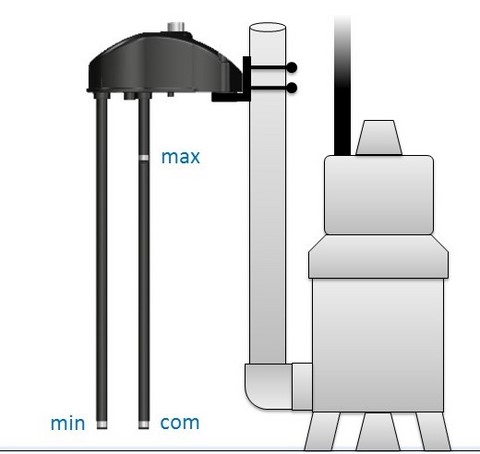

Spider is connected to 3 batons: Common as ground - Min as minimuml level - Max as maximul level

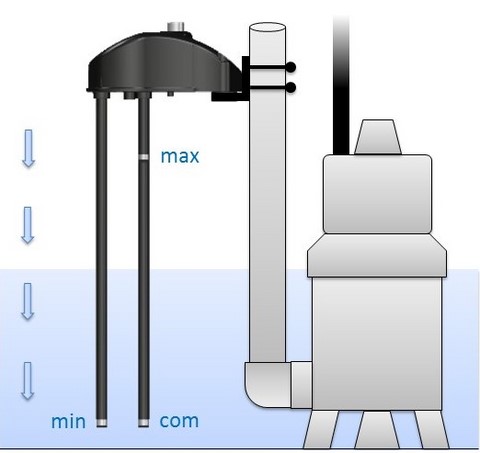

The water reaches the weel and the level increases

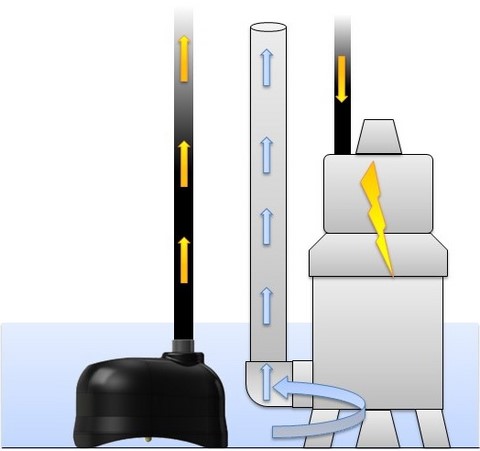

Spider turns ON the pump when the maximum level baton detects the water

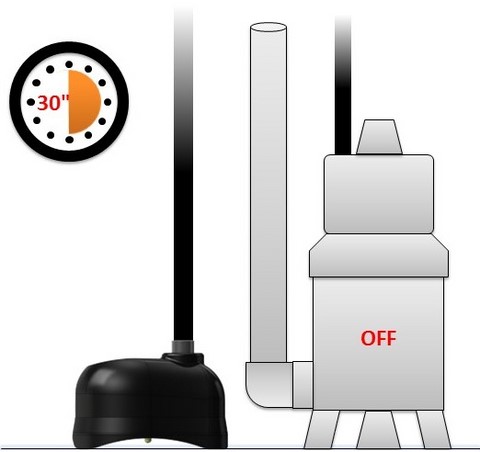

The water level decreases and Spider turns OFF the pump when the minimum level baton doesn’t detect the water anymore

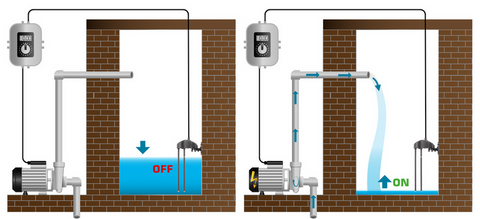

Examples of Applications

SPST-NO

Single Function - Normally Open: Emptying

SPST-NC

Single Function - Normally Closed: Filling

Factory Delay Times

Start

0"

Stop

0"

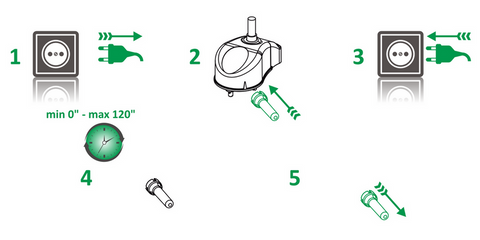

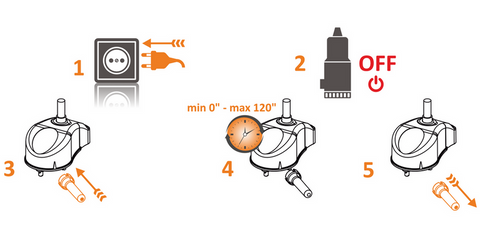

Setting Delay Times

By means of the supplied magnetic key, the customer is able to adjust the delay time of start and stop according to its own needs of use.

Setting Start Delay Time

- Disconnect the plug from the electrical system;

- Put the magnetic key close to the arrow stamped on the side of the electronic controller;

- Connect the plug to turn on the pump;

- Hold the magnetic key in position for how many seconds you wish to delay the starting time (maximum 120 seconds);

- Once you got the desired delay time, remove the magnetic key.

Setting Stop Delay Time

- Connect the plug to the electrical system;

- Wait for the pump shutdown;

- Put the magnetic key close to the arrow shown on the side of the electronic regulator and the pump starts;

- Hold the magnetic key in posion for the seconds necessary to delay the shutdown (maximum 120 seconds);

- Once reached the desired time, remove the magnetic key.

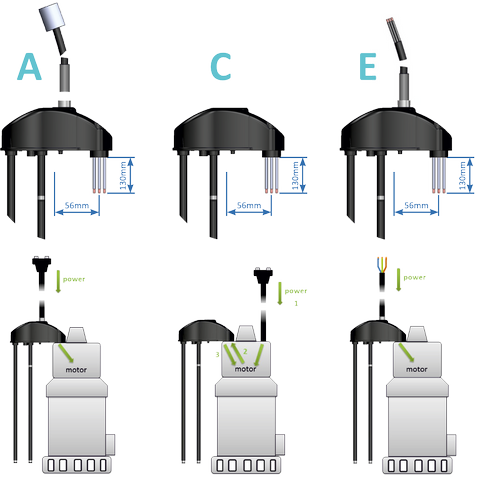

Available Electrical connectons

Standard Applications

Solutions for pump manufacturers

Technical Datas

Casing: Polypropylene

Grommet: TPV

Class Protection: IP 68

Batons: AISI 316-> 250/500/750mm

Grommet: TPV

Class Protection: IP 68

Batons: AISI 316-> 250/500/750mm

MODEL | CABLE TYPE | LENGHT (ft) | POWER SUPPLY | TEMPERATURE | DEPTH |

|---|---|---|---|---|---|

SPIDER A-00B-SPST | SJOW 4AWG16 | 3 / 20 / 30 | 250Vac 10A / 250Vac 1HP / 125Vac ⅓HP | max.+40°C (+104°F) | max.10m (32,8ft) |

SPIDER A-00B-SPST-012 | SJOW 4AWG16 | 3 / 20 / 30 | 12/24Vac/dc 1A | max.+40°C (+104°F) | max.20m (65,6ft) |

SPIDER A-02D-SPST | SJOW 4AWG14+PIGGYBACK PLUG | 15 / 33 | 125V ½HP | max.+40°C (+104°F) | max.20m (65,6ft) |

SPIDER A-03C-SPST | / | / | 250Vac 10A / 250Vac 1HP / 125Vac ⅓HP | max.+40°C (+104°F) | max.20m (65,6ft) |

| SPIDER A-03C-SPST-012 | / | / | 12/24Vac/dc 1A | max.+40°C (+104°F) | max.20m (65,6ft) |

| SPIDER-A-03A-SPST | SJOW 3AWG16+PLUG | 3 / 20 / 30 | 250Vac 10A / 250Vac 1HP / 125Vac ½HP | max.+40°C (+104°F) | max.20m (65,6ft) |

| SPIDER-A-03E-SPST | SJOW 4AWG16 | 3 / 20 / 30 | 250Vac 10A / 250Vac 1HP / 125Vac ½HP | max.+40°C (+104°F) | max.20m (65,6ft) |

| SPIDER A-03E-SPST-012 | SJOW 4AWG14 | 3 / 20 / 30 | 12/24Vac/dc 1A | max.+40°C (+104°F) | max.20m (65,6ft) |

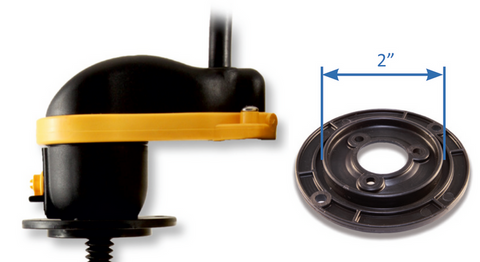

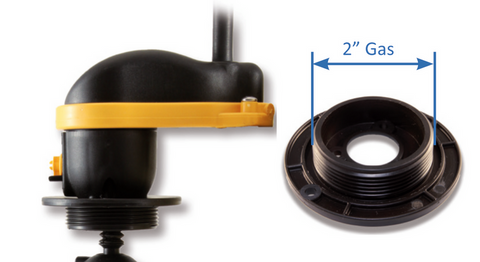

Accessories

Brackets and Supports

(* May not be included)

Polipropylene Bracket

tube or wall fixing

Stainless steel bracket *

aisi 304

Supports

tank fixing

Flanged*

2"

Threaded*

2" Gas

Schuko Piggyback Plug*

The schuko piggyback plug provided with the float switch allows to connect a pump without a switch directly to an electrical socket as to controll the start and stop function.